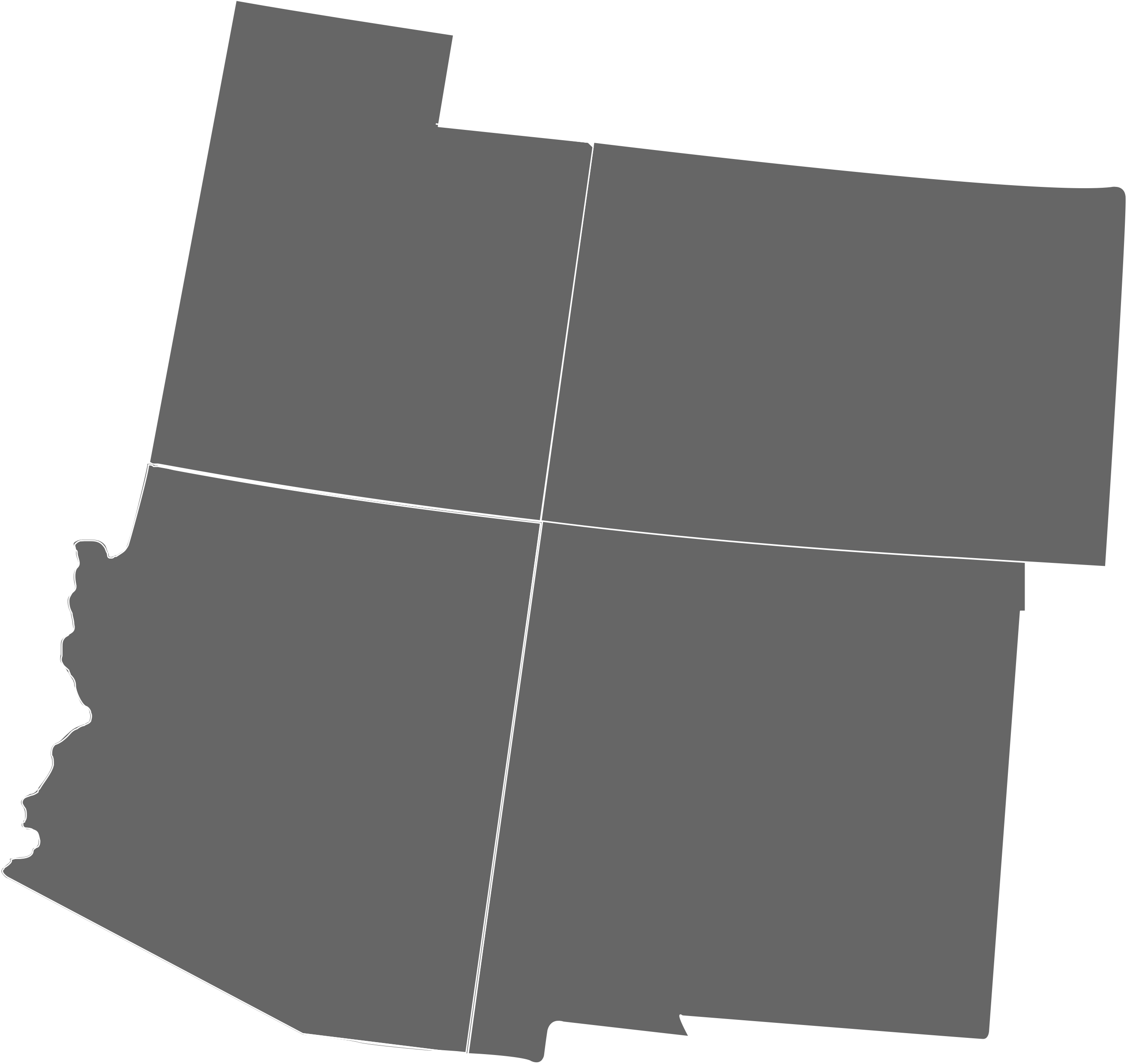

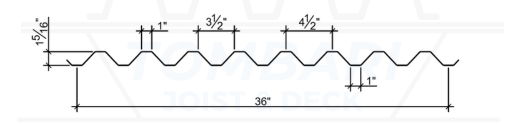

1.0″ FORM DECK

Description

1.0" deep form deck is a shallow steel deck used as a permanent form for concrete slabs, with a depth of 1.0 of an inch. It is commonly used in construction for floors with slabs approximately 3-4" deep. Unlike composite decks, this pan deck does not have embossments and is not designed to bond with the concrete.

Joist & Deck Experts:

Tombari Joist & Deck is the most reliable supplier - we provide accurate bids and expert project execution for joist and deck needs. Our team thoroughly reviews every detail to deliver competitive pricing and efficient project coordination. We are ready and able to support you throughout every phase to ensure your project stays on budget and on schedule.

1" Deck Gauge(s)

26

GAUGE

24

GAUGE

22

GAUGE

20

GAUGE

1.0" Deck Sidelap Attachment(s)

Metal deck sidelap attachments are the fasteners that connect adjacent sheets of steel deck at their overlapping edges, commonly known as side laps. The EOR or design team, is responsible for specifying the type and spacing of sidelap attachments. This specification is crucial as sidelap attachments play a vital role in the structural integrity of the metal deck, the diaphragm to resist lateral forces from wind or seismic activity.

|

NESTABLENestable deck is also designed generally for screw side lap style of B decking. Note the nestable side lap has a lower shear value and must be determined by the EOR. |

Form Deck Finishes:

The metal deck finish is the coating on the steel deck surface, which will vary depending on the application. The EOR or design professional is responsible for specifying the finish of metal deck on a job by job basis.

- Roof deck finishes are most commonly shop coated, G-60 and G-90 varieties.

- Composite deck finishes typically uses galvanized steel to promote a bond with the concrete. Note composite decks cannot have a painted top surface as it creates potential bonding issues between the concrete and the metal deck.

- Form deck finishes are most commonly to be galvanized, or galvanized top with a painted bottom.

PRIME PAINT |

A1008 | Prime Painted Steel Decking: A temporary, provisional primer (gray or white) applied to cold rolled steel, offering protection before field-applied finishes and most often used for roof deck. |

G-30 |

A653 | Galvanized G-60 zinc coated steel is the standard in the deck industry. G30 has approximately 0.3 ounces of zinc per square foot. Generally for warehouse or large sq ft. |

G-60 |

A653 | Galvanized G-60 zinc coated steel is the standard in the deck industry. G60 has approximately 0.6 ounces of zinc per square foot. |

G-90 |

A653 | Galvanized G-90 is typically specified for exterior applications or more corrosive enviromentys with approximately .9 ounces of zinc per square foot. |

FINISH PAINT |

A653 | Finish Paint: Specialty finishes (Epoxy or Tenmic) can be applied either pre- or post-manufacturing, most common in highly corrosive environments rather than architectural coats. |

GALV + PAINT |

A653 | Galvanized + Paint: A combination of galvanization and primer, ideal for projects requiring both corrosion resistance and the ability to apply additional field paints. |

PHOS PAINT |

A1008 | Phosphatized Painted: Steel decking with a phosphatized black surface that develops slight rust before concrete is poured, with the underside painted for additional protection. |

Form Deck Options:

Steel Decking and special variations such as acoustical, cellular, or vented metal decking are generally specified by the EOR or design professional to meet requirements on a project. The choice of a variation is determined during the design phase and typically requires a special manufacturing process, or coil. Note these variations are often indicated structural design drawings or specifications.

|

|

VENTEDSlotted or vented metal roof deck offers factory-punched vent tabs to ensure effective airflow to aid in curing concrete or to prevent moisture from being trapped in the slab during slab waterproofing applications. Consider that when venting metal deck, minor leakage can occur during concrete placement. The row configurations vary by profile; contact us for more details. |